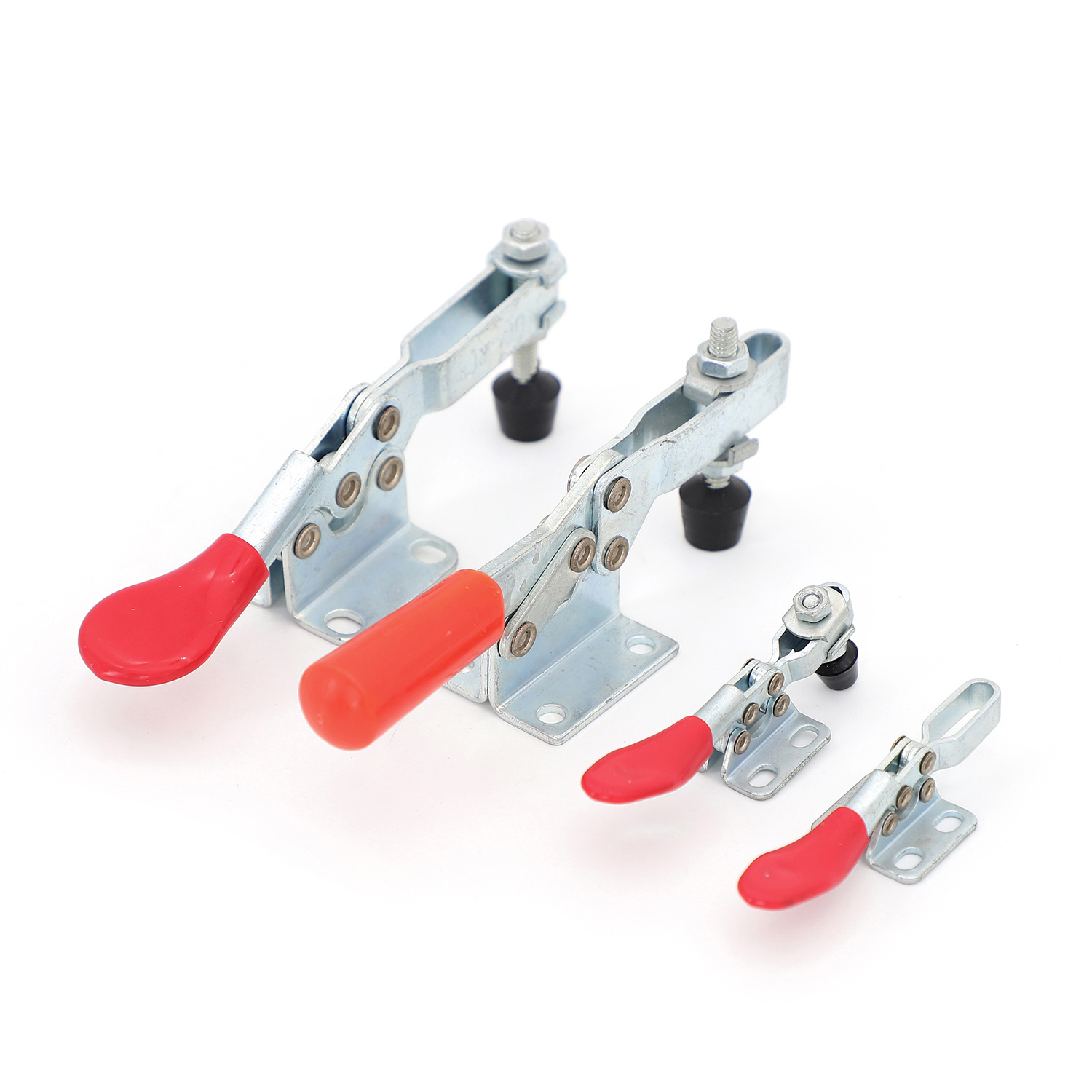

stainless steel spring draw toggle latch

Views : 1851

Update time : 2018-04-16 15:46:29

The stainless steel spring clasp has 304 stainless steel, 201 stainless steel and iron on the choice of production material. We can provide three kinds of material products of the same style for choice. By default, we are all recommending customers to use 304 stainless steel products, because 304 stainless steel products have excellent corrosion resistance, long service life, long term use without rust and easy maintenance.

The stainless steel spring buckle is also a kind of clasp lock. Most of the buckle locks are stamped, and the stainless steel is usually stainless steel plate with the thickness of 1mm, 2mm or 3mm.

The surface treatment of the product mainly depends on the material used by the product. We also mentioned this in the product introduction of "several points to be paid attention to in the production process of industrial hand drawing hand". In general, the stainless steel products are all polished, and the iron material is generally treated with electroplating.

Stainless steel clasp lock surface treatment method is limited, unlike iron material or zinc alloy material production of clasp lock, can be said electroplating, spray paint, and so on, can also make different colors, but because the stainless steel material itself is specific corrosion protection and rust prevention characteristics, it is not necessary to do other surface treatment. On the other hand, stainless steel material is not easy to absorb electroplating or spray paint materials, the use of a long time is easy to fall, so a comprehensive consideration, the most part of the 304 stainless steel material on the market or other products are polished or drawing surface treatment, such as this door lock.

Related News

Read More >>

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Jul .21.2023

Huiding Hardware had participated in the industrial exhibition in Yekaterinburg, Russia from July 10th to 13th, 2023. The main exhibited products include buckles, clamps, hinges, handles, indexing pins, and stamping parts.

Toggle latch material and finish

Toggle latch material and finish

May .06.2022

Zinc Plated Iron

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

English

English  Deutsch

Deutsch  Français

Français  Español

Español  Português

Português