Installation and handling of toggle

Views : 918

Author : Susan

Update time : 2020-12-17 16:38:04

Installation and handling of toggle

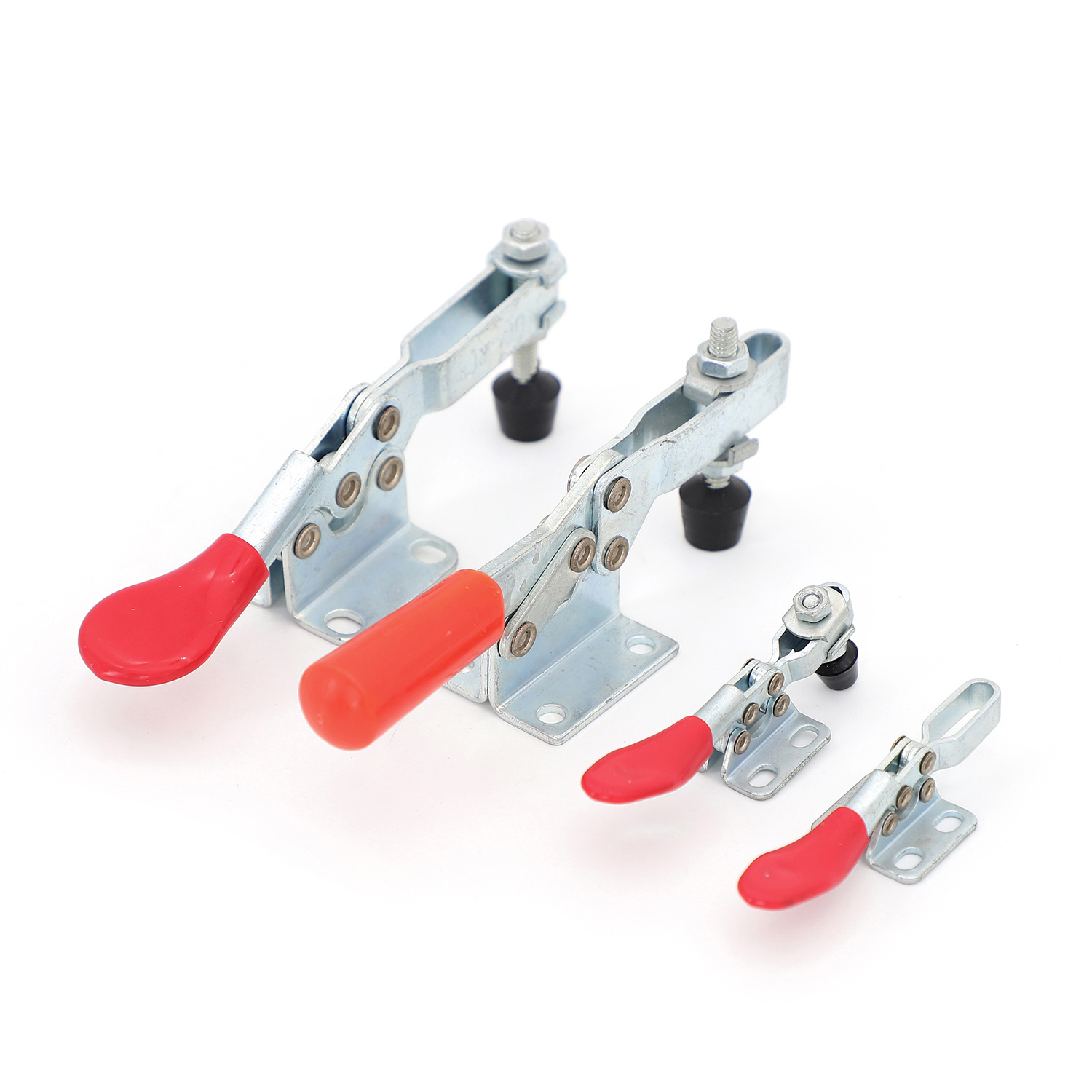

The design form of toggle latch is various, go up in application also more extensive.The definition of simple snap-lock is mainly used in some case structures, such as toolbox, The combination of the toggle latch and the box body should be done after the installation of the joint and even the surface of the two objects to do the appearance treatment.

For example, for the ordinary material of the toggle latch in the installation is completed after the need to do protection measures on the surface of the iron material so as not to rust, and stainless steel toggle latch need not do too much anti-rust treatment, in the installation to minimize the damage of tools on the toggle latch surface, treatment can be good installation joint.

Test box, soundproof box, or the case where two objects need to be fastened together.The iron box toggle latch holds the two parts together and can be loosened quickly, so that the two objects can be quickly joined or separated.

Some simple fasteners can even be adjusted, which we call metal fasteners.

Use good toggle latch should achieve stable installation above all, normal toggle latch has two kinds, one is to take lock hole, so the device is very brief and convenient.Of course, sometimes according to the actual situation, the required hole is different, then this is not with keyhole, this designer has different choices according to the needs of different users;That would require a different installation.

Generally, the fasteners have mounting holes, and there are few fasteners without mounting holes. For the fasteners with mounting holes, they only need to be installed directly with screws, and it is more convenient to remove them if there are good ones.Fasteners without mounting holes shall be welded and installed directly.

This installation method is recommended to be considered carefully, if once the welded product and parts are fixed, it is difficult to modify.

And if it is a temporary fixed effect, can choose spot welding, spot welding in a few important positions, when taking apart with a grinding machine to grind the welding spot can be.Of course, the required products and the raw materials of the parts meet the requirements of welding.

The design form of toggle latch is various, go up in application also more extensive.The definition of simple snap-lock is mainly used in some case structures, such as toolbox, The combination of the toggle latch and the box body should be done after the installation of the joint and even the surface of the two objects to do the appearance treatment.

For example, for the ordinary material of the toggle latch in the installation is completed after the need to do protection measures on the surface of the iron material so as not to rust, and stainless steel toggle latch need not do too much anti-rust treatment, in the installation to minimize the damage of tools on the toggle latch surface, treatment can be good installation joint.

Test box, soundproof box, or the case where two objects need to be fastened together.The iron box toggle latch holds the two parts together and can be loosened quickly, so that the two objects can be quickly joined or separated.

Some simple fasteners can even be adjusted, which we call metal fasteners.

Use good toggle latch should achieve stable installation above all, normal toggle latch has two kinds, one is to take lock hole, so the device is very brief and convenient.Of course, sometimes according to the actual situation, the required hole is different, then this is not with keyhole, this designer has different choices according to the needs of different users;That would require a different installation.

Generally, the fasteners have mounting holes, and there are few fasteners without mounting holes. For the fasteners with mounting holes, they only need to be installed directly with screws, and it is more convenient to remove them if there are good ones.Fasteners without mounting holes shall be welded and installed directly.

This installation method is recommended to be considered carefully, if once the welded product and parts are fixed, it is difficult to modify.

And if it is a temporary fixed effect, can choose spot welding, spot welding in a few important positions, when taking apart with a grinding machine to grind the welding spot can be.Of course, the required products and the raw materials of the parts meet the requirements of welding.

Related News

Read More >>

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Jul .21.2023

Huiding Hardware had participated in the industrial exhibition in Yekaterinburg, Russia from July 10th to 13th, 2023. The main exhibited products include buckles, clamps, hinges, handles, indexing pins, and stamping parts.

Toggle latch material and finish

Toggle latch material and finish

May .06.2022

Zinc Plated Iron

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

English

English  Deutsch

Deutsch  Français

Français  Español

Español  Português

Português